Construction of an offshore wind turbine manufacturing plant

The offshore wind turbine plant

The Joannes Couvert quay project in the Port of Le Havre involves the construction of an offshore wind turbine manufacturing plant for Siemens Gamesa Renewable Energies (SGRE). It is the largest manufacturing project in the history of the French renewable energy industry. The 36-hectare site will produce turbine blades, as well as assembling and repairing turbine nacelles. It will play a leading role in the development of new wind farms offshore Normandy and Brittany.

Worksite operations include the construction of two production buildings with office spaces, and storage/transport areas for wind turbine components. A new WWTP (wastewater treatment plant) will also be built as part of the project.

The choice of foundations

Because of the thick layers of silt beneath the heavy operating loads imposed by the new production plant, the initial foundation solution was to implement piles the entire structural footprint to reduce settlement.

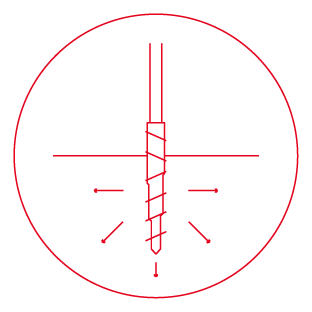

As a specialist in soil improvement technologies, Menard France was able to propose an alternative solution to reduce settlement : Controlled Modulus Column (CMC) rigid inclusions beneath the paved surfaces of several production areas, beneath the foundations and paved surfaces of peripheral buildings, and beneath the WWTP.

This shallow foundation solution implemented in close cooperation with the deep foundation contractors (Soletanche Bachy Fondations Spéciales & Botte fondations) successfully met the technical and economic challenges of the client. Menard France is working on a co-contractor basis with VINCI and Equans companies.

A tight schedule

To complete the work within the tight schedule allowed, Menard France brought in 3 rigid inclusion rigs. Around 6,200 (300 mm diameter) CMCs were then installed at depths of between 18 and 30 metres.

Ensuring UXO safety for drilling operations

Prior to the commencement of drilling, Menard France also conducted a detection survey to identify any unexploded ordnance (UXO). This survey has the joint benefits of ensuring the safety of drilling operations and removing the need to purge and conduct mine clearance operations in the subsoil, thereby limiting operational costs. UXO detection enables the relocation of inclusions or piles where high levels of magnetic signal are detected. The detailed design of the structure can then be modified accordingly.