Dynamic replacement is a ground improvement technique that reinforces fine grained soils with a network of dynamically pounded pillars.

Presentation and key elements

What are dynamic replacement and why do we use it?

Dynamic replacement is an extension of dynamic compaction. This method combines advantages from both dynamic compaction and stone columns by creating large-sized dynamic replacement inclusions or pillars with high internal shear resistance. This technique is well suited to highly compressible and weak soils and can be applied to structures with high loading (high backfill, storage tanks, etc.). This technique results in improved bearing capacity of the poor soils and the subsequent reduction and control of total and differential settlements. An additional benefit is that the dynamic replacement pillars allow for rapid drainage of the ground.

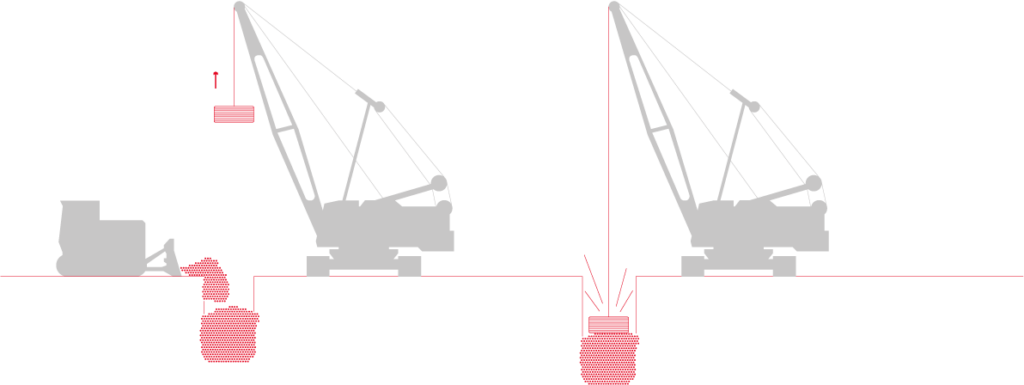

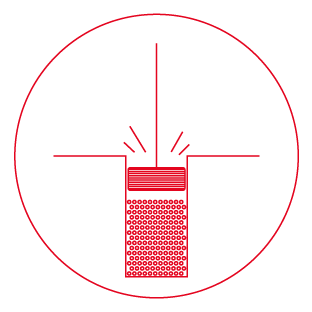

Basic principle of dynamic replacement

If the ground cannot be dynamically compacted directly due to high fine content within the soil, a fill material must be added. The incorporation ratio is generally between 10 and 15%. In this application, the tamping energy drives granular material down into the compressible soils to form large diameter reinforcement columns (with diameter around 2 to 3.5 m). Additional improvement can be obtained in the underlying layers through the transmission of the energy of the weight at depth.

Execution of dynamic replacement

The technique can be carried out with or without pre-excavation. Pounding and filling of the reinforcement pillars alternates accordingly during execution. The material incorporated is either placed over the whole treatment surface prior to pounding and then pushed into the pillars during the project or it can be stored at regular intervals around the worksite and directly incorporated in the pillars.