DC/DR for the new LEVIS warehouse in Germany!

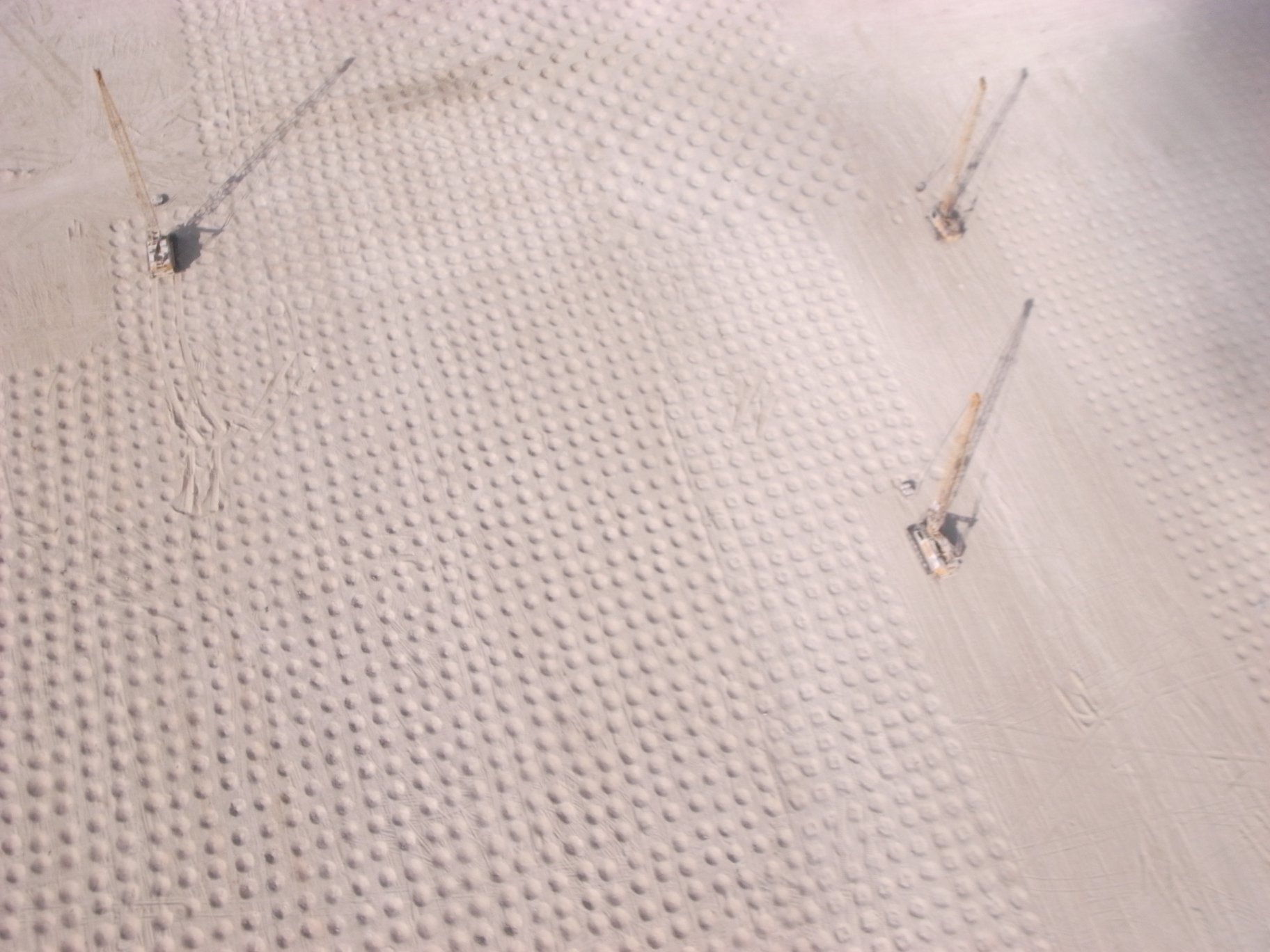

In the first months of the year 2022, Menard improved the uncontrolled fills and deposits of clay, silt and sand layers for the new high bay warehouse of Levi Strauss & Co in Dorsten (Germany). In sandy areas classic Dynamic compaction could be used. In silty and clayey areas we carried out Dynamic replacement method to create large and impressive stone columns.

The two cranes dropped the pounders with weights of up to 28 tons on more than 1,500 points.

To backfill the craters crushed concrete Materials were used. As a result, resources of natural granular material could be saved. Compared to other methods of soil improvement and the classical piling solution, a lot of GWP (CO2 eq) was saved and brought benefit to the Positive Footprint Wearhouse® of LEVIS, which is also in line with our Less is more Menard approach.

The final compaction phase for Ironing of the >25.000m² area was realized by our Menard Rapid Impact Compaction (RIC).

The impressive building is currently being constructed by Bremer and we wish all those involved in the project continued success!

The Menard group develops foundation solutions based on ground improvement and reinforcement technologies. Its treatments eliminate the need for the deep foundations traditionally used to support surface structures.