Extending the runway at Charleroi Airport

The majority of work now underway at Charleroi Airport in Belgium on behalf of SOWAER (the Wallonia Airports Operating Company) focuses on extending the length of the runway from 2,550 to 3,200 metres. Begun last year, these upgrades will allow Brussels South Charleroi Airport (BSCA) to continue its expansion to accommodate larger aircraft and offer passengers new routes.

Soil compressibility

The runway extension project involves major earthworks and backfilling operations in preparation for tarmac laying. In practical terms, building the new section at the same level as the existing runway requires up to 6 metres depth of technical backfill. Without additional work, the weight imposed by this backfill on the compressible soil layers below would result in a degree of settlement that the structure of the future runway would be unable to support.

So before backfilling operations, Menard was brought in to identify and characterise those areas to be reinforced, and prepare a precise phasing schedule for optimising production prior to soil reinforcement.

The ground improvement solution

Below ground

The solution involves the construction of 6,448 stone columns flexible inclusions between 6 and 9 metres deep over an area of 22,500 m². The columns strengthen the compressible layers of anthropogenic fill and quaternary clayey silts and terminate in the compact tertiary sandy clay layer.

Above ground

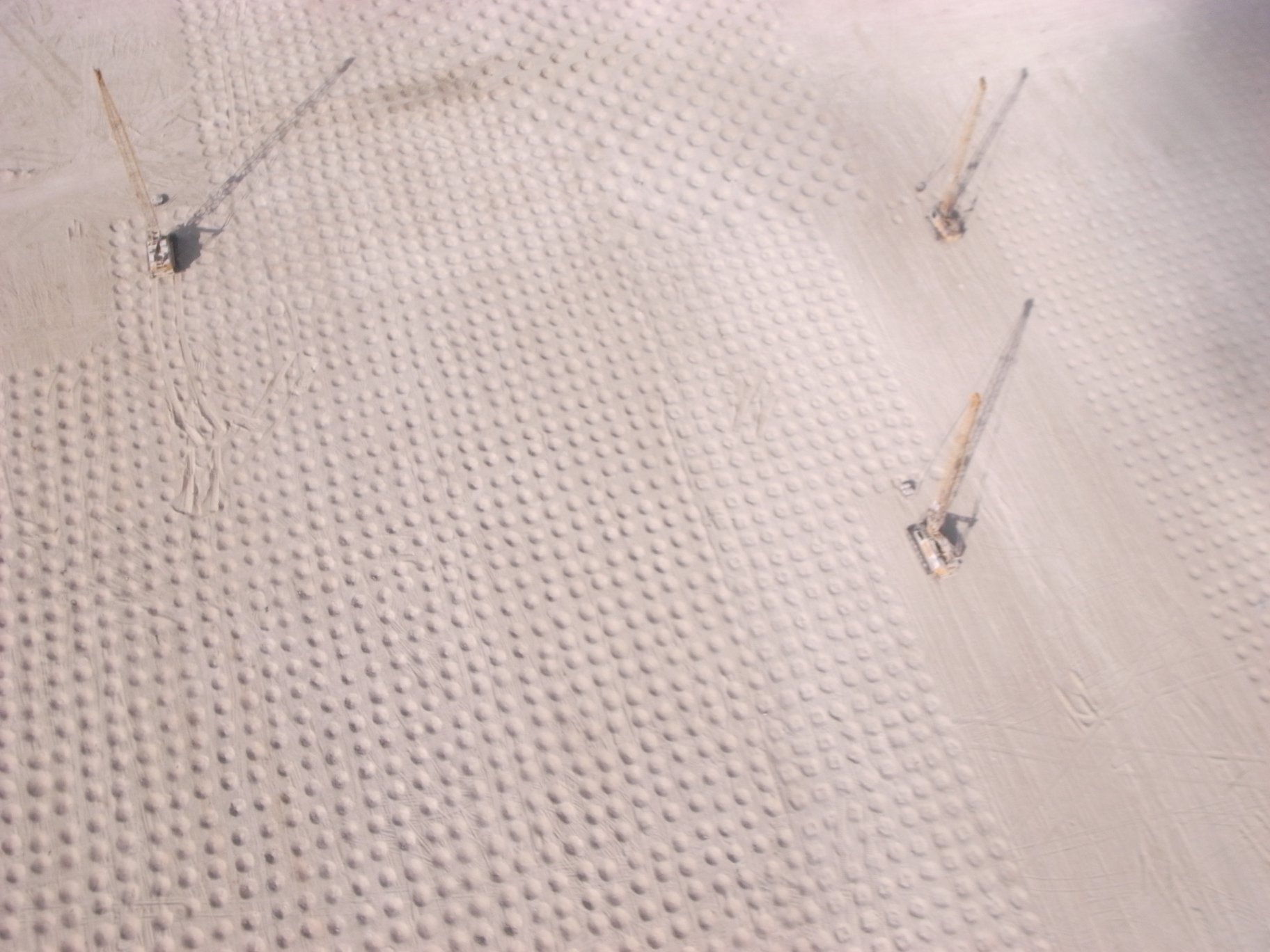

Our teams have to work around the significant constraints imposed by airport activity, which include maintaining air traffic during work on site, and scheduling operations over day shifts and night shifts.

Daytime working must comply strictly with the height limitations dictated by the takoff cone of individual aircraft types. Although the height limitation is suspended at night, working hours are reduced (the maximum period is from 11:30 pm to 05:30 am) and governed by the variability of air traffic schedules.

Two stone column machines are used for this major project to offer maximum flexibility in terms of soil conditions and on-site constraints. A compact short-mast (SPD) drilling rig delivers maximum production during the day, while a traditional Enteco E500 rig reaches greater depths at night.

The work begun by Menard in October 2019 were completed in Quarter 2 of 2020 ahead of the new section of runway being commissioned in 2021.

Project owner: SOWAER

Prime contractor: The WANTY + TRBA consortium

Subcontractor: MENARD NORD AND BELGIUM

The Menard group develops foundation solutions based on ground improvement and reinforcement technologies. Its treatments eliminate the need for the deep foundations traditionally used to support surface structures.