Menard Vacuum™ is used to accelerate consolidation of cohesive, highly compressible soils. The process consists in creating a negative pressure under an airtight membrane laid over the soil, which generates atmospheric pressure on the soil, equivalent to the pressure exerted by a 4 metre embankment.

Presentation and key elements

What is Menard VacuumTM and why do we use it?

When a load is applied on saturated cohesive compressible soils (clays, silts), the structure can settle for a long period of time (up to 10 to 20 years).

Menard Vacuum™ is a ground improvement technique, created and developed by Menard, which is used to control long term residual settlement in this type of soils within acceptable limits.

Basic Principle of Menard VacuumTM

Cohesive soils (clayey soils) are generally characterised by having a low permeability. Consolidation of a cohesive soil relies on the ability to evacuate water out of the soil matrix and this process can be very long.

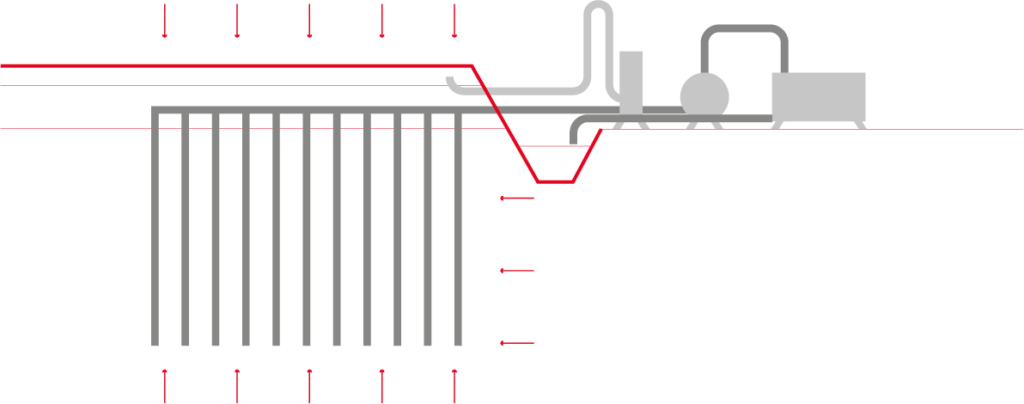

Menard Vacuum™ is an atmospheric consolidation system used to accelerate consolidation of cohesive, highly compressible soils. The process consists in creating a negative pressure under an airtight membrane laid over the soil, which generates atmospheric pressure on the soil, equivalent to the pressure exerted by a 4 meter embankment.

This technique can substantially reduce consolidation time thanks to early pre-loading as soon as the system is in place and without risk of ground failure. The isotropic nature of the Menard Vacuum™ load and the “artificial beam” generated by the vacuum between the horizontal drains and the membrane have a strong stabilising effect on the fill.

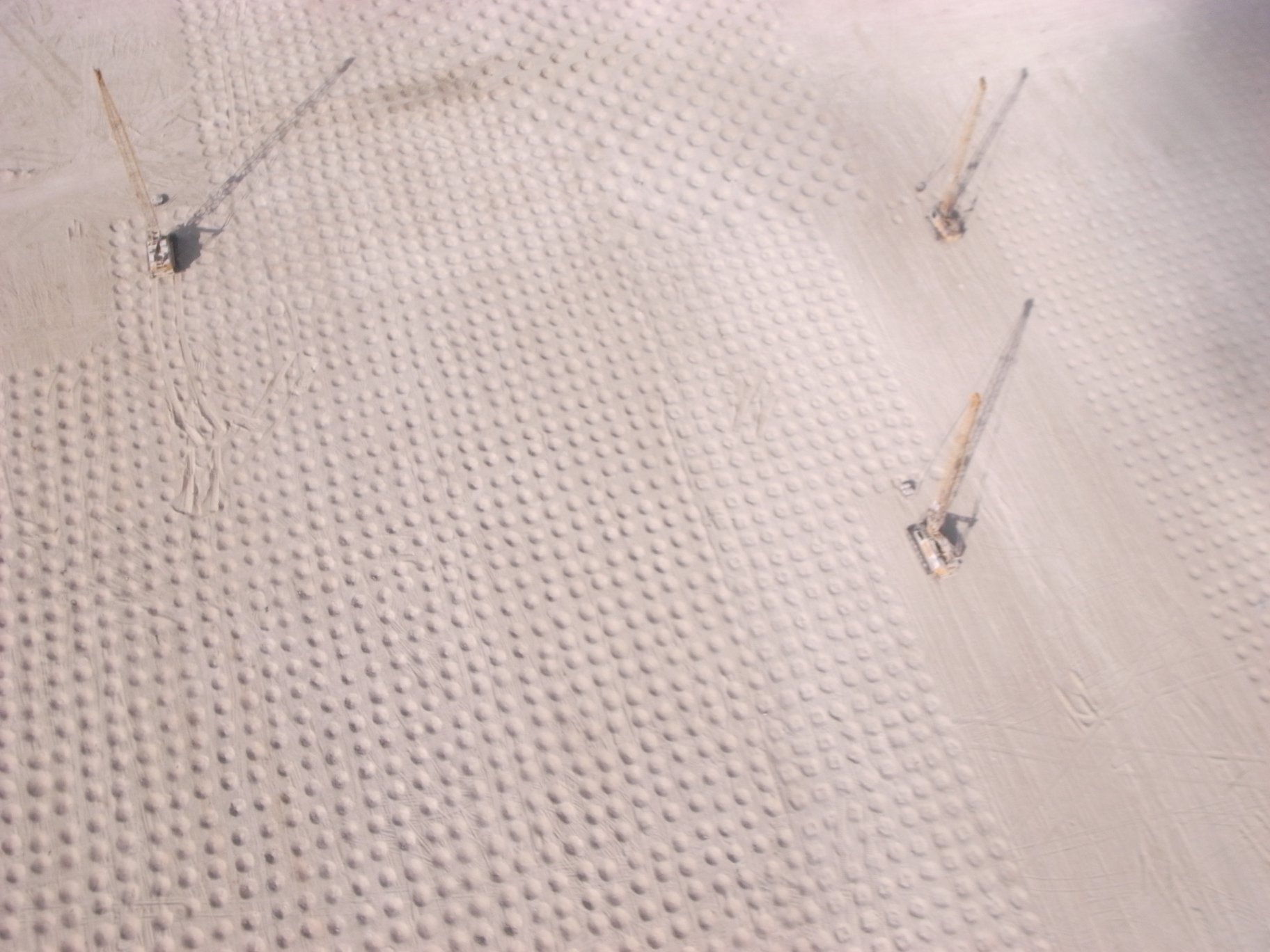

Execution of Menard VacuumTM

The procedure consists of installing a vertical and horizontal draining system combined with a vacuum pumping system under an airtight impervious membrane. The area is sealed by sealing the membrane into a network of peripheral trenches.